When a boiler operates with steam pressure greater than 80 bars, it is referred to as a high-pressure boiler above 80 bars. High pressure is widely used in power generation in thermal power plants. Read More…

We strive for the best at Unilux Advanced Manufacturing LLC. Our boilers are designed with superior materials. We are proud to say that we produced the world's first UL/FE boiler and our units provide the highest levels of safety and accountability.

As the inventor of the vertical tubeless boiler, Fulton has a reputation for success dating back to 1949. We`re a global manufacturer of steam, hot water and hydronic boilers, thermal fluid heaters, and custom engineered systems.

Miura Boiler Co., Ltd. has been manufacturing, designing, engineering and servicing gas, oil, coal, wood, solid waste, biomass & hybrid fuel-fired steam & gas and condensing since our inception. With installations across all industries worldwide, We are recognized for the highest code standards, innovative engineering and design, Energy Star rating, fully Integrated controls, and renewable,...

Indeck has the largest inventory of steam generating systems, a custom boiler design team and our own boiler manufacturing plant . Indeck is the complete steam power solution provider with emergency rental of 25,000 pph trailer-mounted rental boilers to the design of large custom million pound boilers. Our expertise includes watertube, mobile, packaged, waste heat, solid fuel, biomass and fire...

Superior Boiler Works specializes in industrial boilers, steam boilers, hot water boilers, gas fired boilers, high pressure boilers, electric boilers and mobile boilers. Superior offers a wide variety of standard models as well as custom design engineering for special applications.Visit our website or call us today to learn more!Let us be the source for your next project!

With over 60 years of experience in sales, service, rental & installation of packaged boilers & boiler room equipment, Smith Hughes has the expertise & dedication to meet your needs for everything in your boiler room, including 24-hour emergency service & turn-key design/build for a customized, complete mobile boiler room package. Check out rental & refurbished boilers with nationwide delivery.

Nationwide Boiler is a leading supplier of new and reconditioned boilers for industrial facilities worldwide. We’re a manufacturer’s representative and stocking distributor for B&W package watertube boilers and Superior package firetube boilers, and we have fully reconditioned boilers in a variety of types and sizes. With sales, service and equipment depots throughout the U.S., we strive to...

More High Pressure Boiler Manufacturers

Classification of High-Pressure Boilers

Modern high-pressure boilers can be classified according to the numerous categories below.

Types of High-Pressure Boilers

- Lamont Boilers

- Benson Boilers

- Loeffler Boilers

- Schmidt-Hartmann Boilers

- Velox Boilers

- Super Critical Boilers

- Waste Heat Recovery Boilers

High-pressure boilers can be divided into natural, forced, and once-through boilers. We look at some of these high-pressure boiler types below.

Lamont Boilers

This boiler uses forced circulation to operate. The drum receives feed water, the water in the drum is pumped to the evaporator portion, and the water and vapor are then returned to the drum. After being transported to the superheater, the steam in the drum is fed to the prime mover. Compared to standard water tube boilers, La Mont's initial designs proved lighter, safer, and capable of higher heat transfer rates and evaporation per square foot. They also demonstrated that the circulation of vaporized water at a differential pressure of 2.5 bar was 8 to 10 times greater.

Benson Boilers

When operating at part-load below 60° MCR, a Benson boiler, a type of once-through boiler that Marc Benson invented and patented in Germany in 1923, incorporates recirculation features. Small diameter tubes with a bore of about 25 mm are typically used in Benson boilers to create the furnace envelope. High subcritical or supercritical pressure feed water enters the furnace's bottom and is evaporated to high quality in the spiral section.

Before the steam/water mixture is supplied to the open boiler pass, a balancing header is frequently placed near the top of the furnace to eliminate any changes in steam quality caused by variances in heat absorption in different parallel spiral circuits. It undergoes superheating in pendant tube banks after superheating in the furnace envelope's upper portions. The balancing header separates the extra liquid when the furnace flow rate exceeds the total boiler demand for steam at low loads. The flue gases are used in fossil fuel-fired boilers for reheating, economizing, and air-heating purposes.

Waste Heat Recovery Boilers

Waste heat recovery boilers convert heat from industrial furnaces, refuse incinerators, and industrial waste into usable and efficient thermal energy. As a result, the waste heat recovery boiler is improving thermal efficiency, saving energy, and protecting the environment in industrial civilization.

This waste heat is produced from steel, non-ferrous metal, chemicals, cement, and other materials. Waste heat recovery boilers are improving thermal efficiency, saving energy, and protecting the environment in industrial civilization.

Working Principle of High-Pressure Boilers

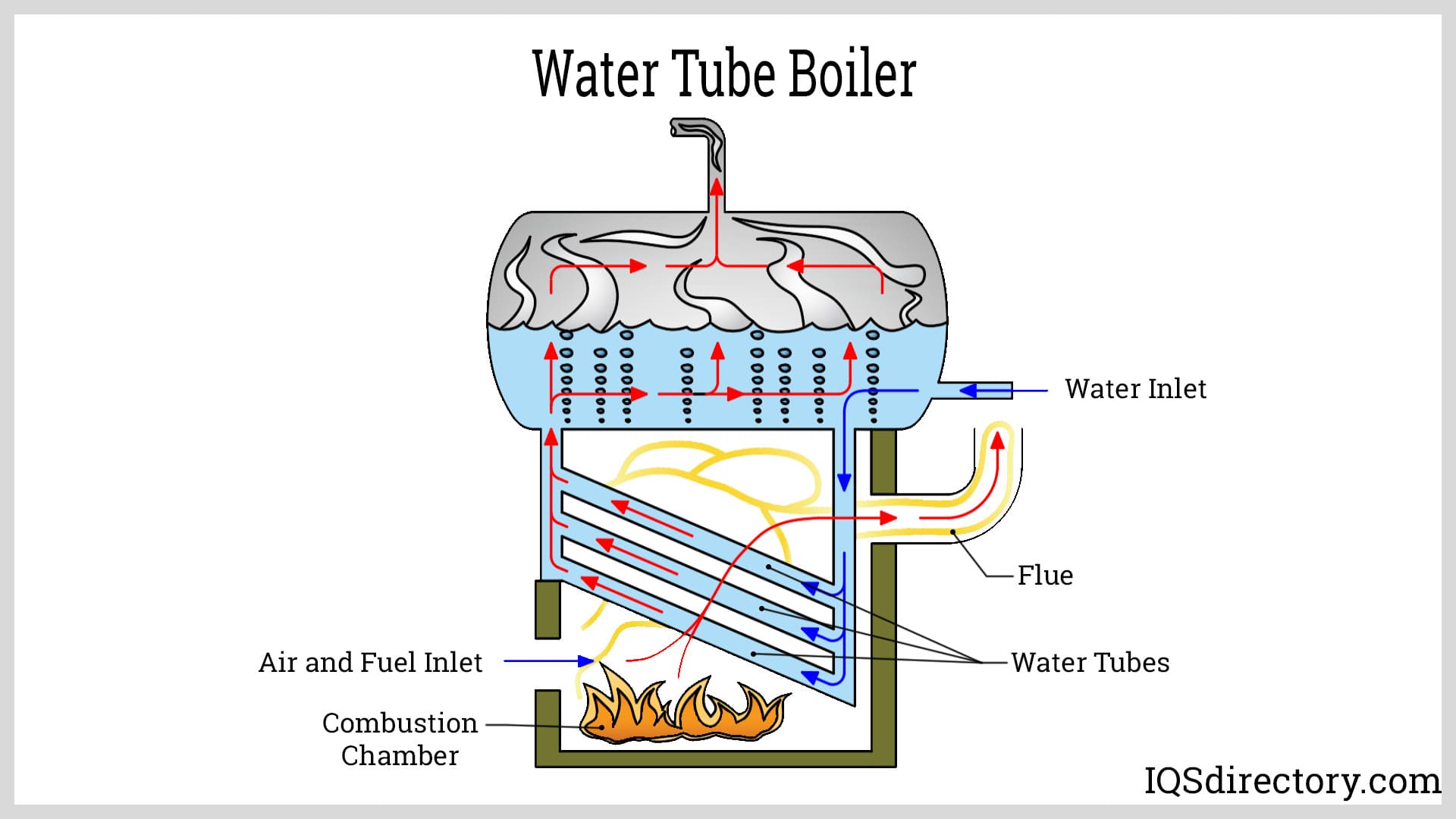

Water cycles repeatedly from the shell (water drum) to the water tubes and back to the shell before being converted to steam. The water warms up during circulation as it comes into indirect touch with flue gases that conduct heat through tubes.

Circulation ratio is a significant consideration while developing water tube boilers overall. There are two fundamental concepts for water tube boilers based on circulation: Forced circulation and natural circulation boilers.

Natural circulation boilers are the sort of boilers where water circulates spontaneously due to the difference in density. The variation in temperature between cold and hot water causes the density to differ. The circulation ratio is crucial when designing natural circulation boilers to avoid overheating or tube bursts.

In contrast, the water circulation in a forced circulation boiler depends on a secondary pump that is mounted after the feedwater pump (primary pump) and that, depending on the design and safety requirements, either forces up or forces down the circulation ratio.

Applications of High-Pressure Boilers

- The expansion of steam in a steam turbine or engine can produce mechanical or electrical power.

- Heating: In cold climates, steam can heat residential and commercial buildings and create hot water for domestic usage.

- Industrial processes: The sugar, cement, agriculture, and chemical sectors can utilize steam for industrial processes like sizing and bleaching in the textile industry.

Advantages of High-Pressure Boilers

- The utilization of several small-diameter tubes effectively utilizes the heat of combustion.

- Powertherm boilers have a parallel set of tubes to prevent significant resistance to water flow.

- Typically, the components of steam boilers are arranged horizontally for greater accessibility and operating comfort.

- The risk of warming is decreased because the elements are heated evenly. As a result, the thermal stress disadvantage is also minimized.

- The rapid water flow through the boiler tubes eliminates the propensity for scale formation.

- Boilers that operate at high pressures can run on liquid or gaseous fuels.

Disadvantages of High-Pressure Boilers

- The tubes may become overheated if there is not enough water flow.

- The interior surfaces of the tube are where bubbles form, slowing down the heat transfer rate.

Choosing the Proper High-Pressure Boilers Company

To make sure you have the most productive outcome when purchasing High-Pressure Boilers from a High-Pressure Boilers Manufacturer, it is important to compare at least 5 Companies using our list of High-Pressure Boilers manufacturers. Each High-Pressure Boilers Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each High-Pressure Boilers business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple High-Pressure Boilers businesses with the same message.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

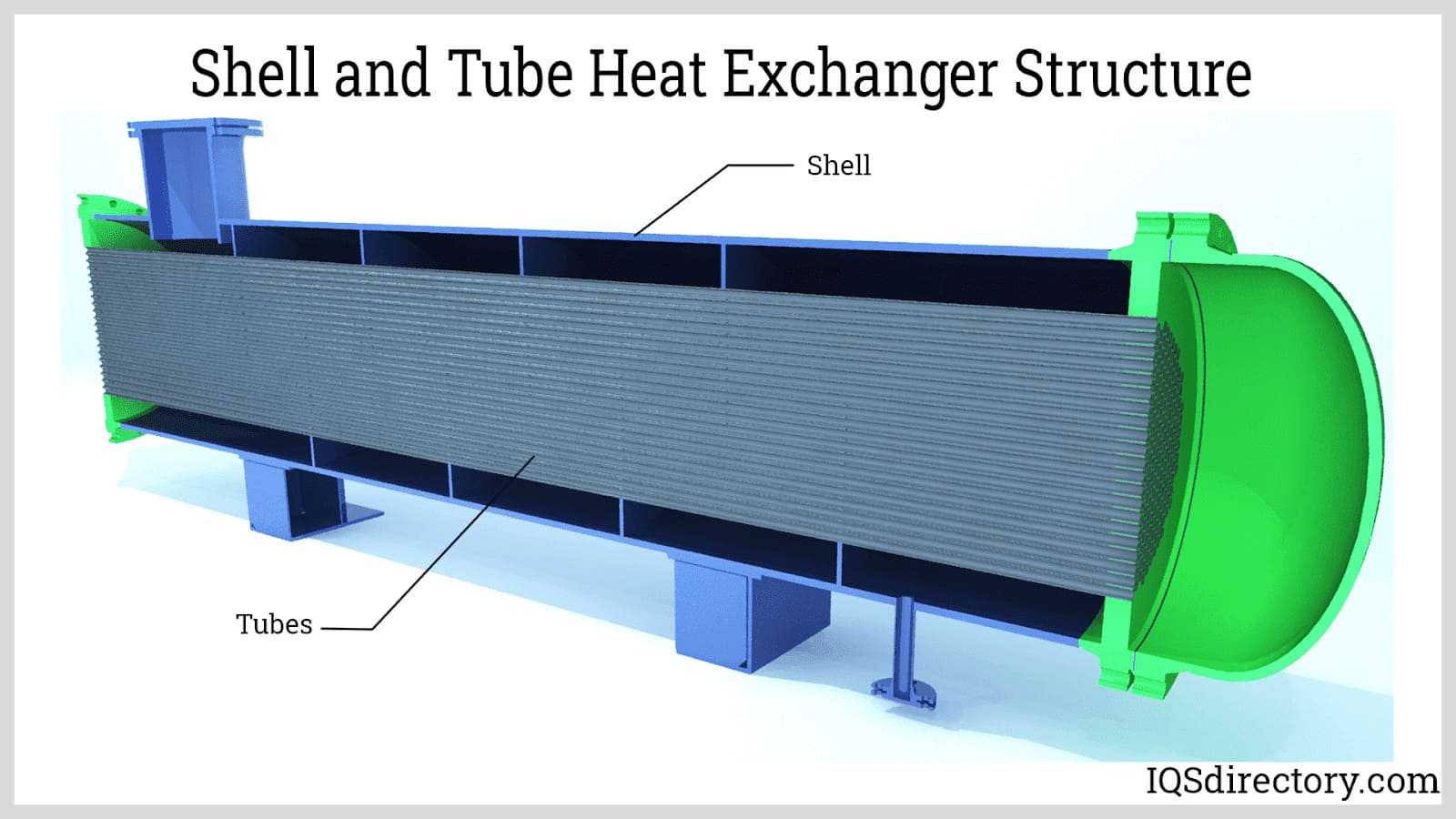

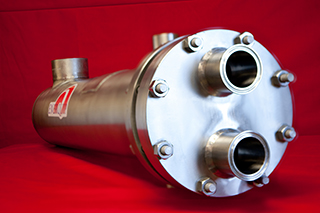

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services