Water vapor is created when fuel is burned in a boiler. The heat in this water vapor, often known as steam, can help warm the central heating system. However, until the invention of condensing boiler technology, this heat was lost through the flue pipe. Read More…

We strive for the best at Unilux Advanced Manufacturing LLC. Our boilers are designed with superior materials. We are proud to say that we produced the world's first UL/FE boiler and our units provide the highest levels of safety and accountability.

As the inventor of the vertical tubeless boiler, Fulton has a reputation for success dating back to 1949. We`re a global manufacturer of steam, hot water and hydronic boilers, thermal fluid heaters, and custom engineered systems.

Miura Boiler Co., Ltd. has been manufacturing, designing, engineering and servicing gas, oil, coal, wood, solid waste, biomass & hybrid fuel-fired steam & gas and condensing since our inception. With installations across all industries worldwide, We are recognized for the highest code standards, innovative engineering and design, Energy Star rating, fully Integrated controls, and renewable,...

Indeck has the largest inventory of steam generating systems, a custom boiler design team and our own boiler manufacturing plant . Indeck is the complete steam power solution provider with emergency rental of 25,000 pph trailer-mounted rental boilers to the design of large custom million pound boilers. Our expertise includes watertube, mobile, packaged, waste heat, solid fuel, biomass and fire...

At California Boiler, we dedicate ourselves to delivering high-performance boiler solutions that meet the diverse needs of industries across the region. As a team, we design, supply, and support a full range of boiler systems, from standard hot water and steam units to specialized, high-capacity equipment tailored to unique applications.

At Burnham Commercial Boilers, we take pride in being a trusted name in the manufacturing and engineering of high-quality boilers designed to deliver dependable heating solutions for commercial and industrial applications. With decades of experience and innovation behind us, we focus on building equipment that meets the rigorous demands of facilities that require reliable performance, energy...

Nationwide Boiler is a leading supplier of new and reconditioned boilers for industrial facilities worldwide. We’re a manufacturer’s representative and stocking distributor for B&W package watertube boilers and Superior package firetube boilers, and we have fully reconditioned boilers in a variety of types and sizes. With sales, service and equipment depots throughout the U.S., we strive to...

More Condensing Boiler Manufacturers

What are Condensing Boilers?

Consequently, the traditional boiler was losing up to 30% of the heat it generated. In order to make up for the loss, the boiler would, therefore, need to burn additional fuel. The "Flue Gas Recovery System," which is used by condensing boilers, recycles the heat from the steam and prevents heat loss. As a result, heating systems today are more effective than ever.

How Condensing Boilers Work

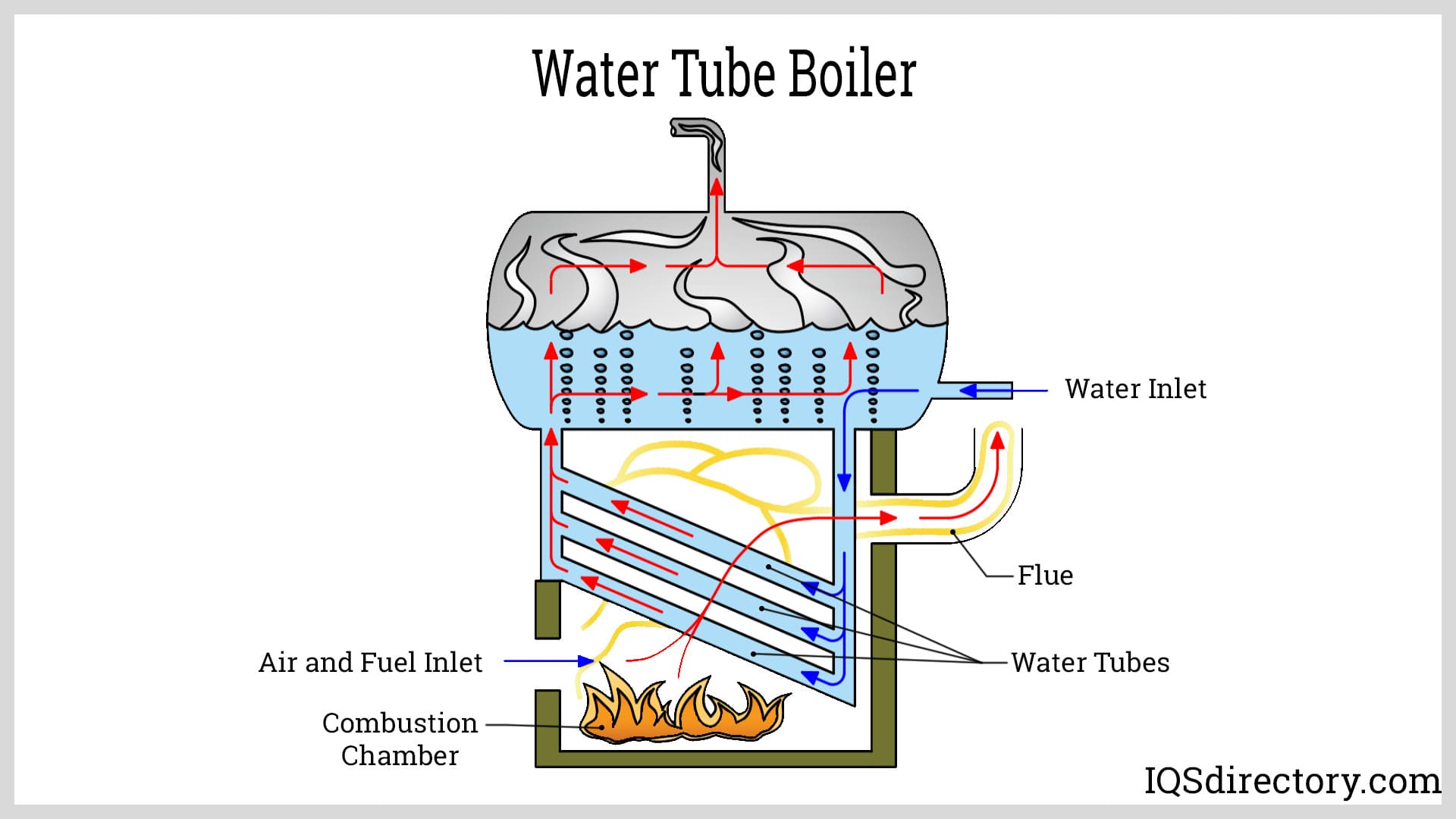

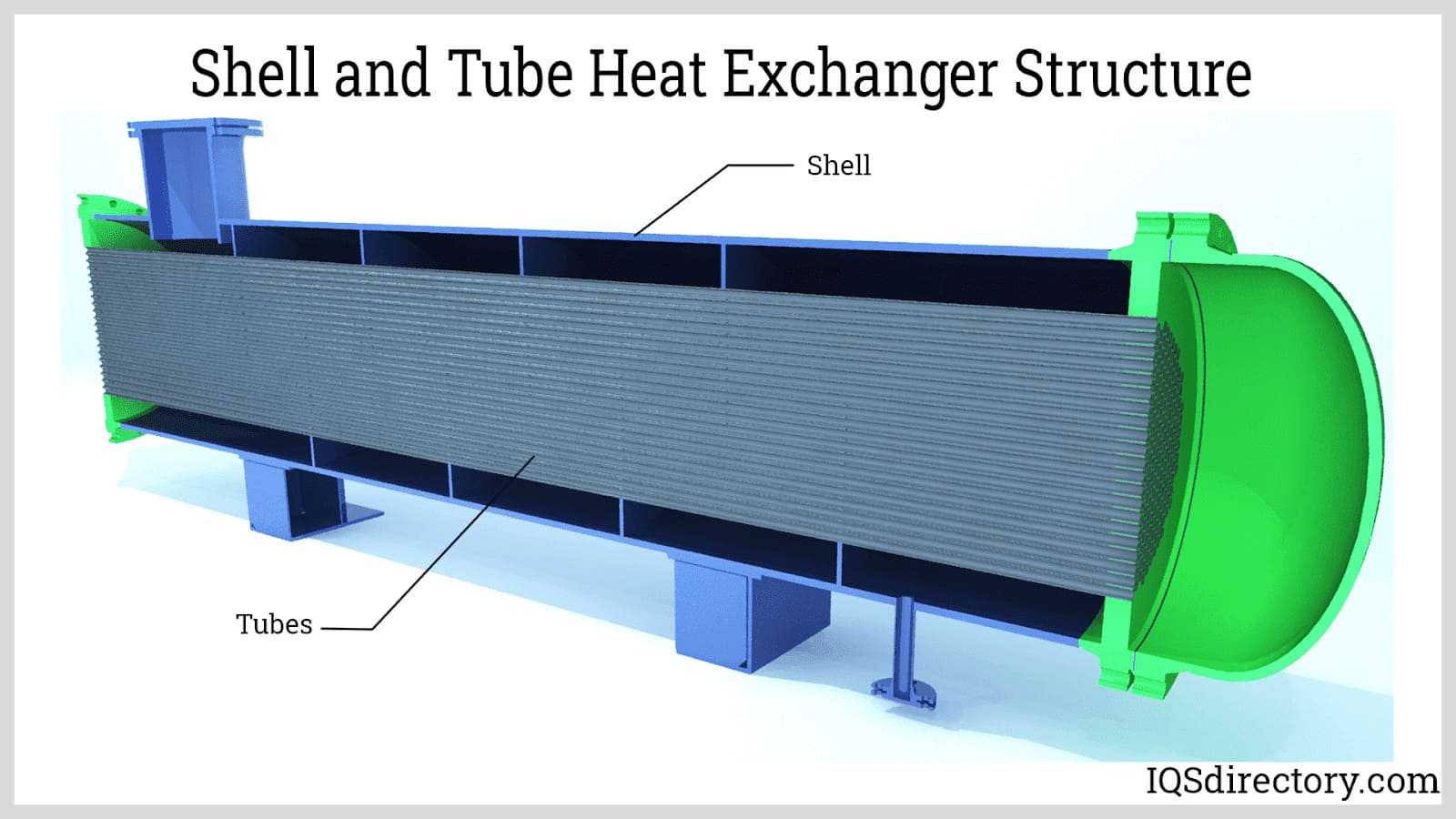

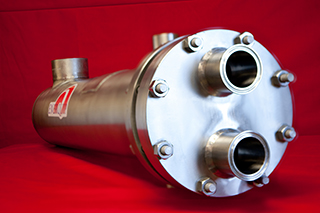

The heat that would otherwise be lost is captured by the flue gas recovery system, which uses two heat exchangers in condensing boilers. Burning the fuel causes waste gasses to be produced while the central heating boilers generate warmth. In order to prevent harm to people, or damage to a property, waste gasses needed be released into the atmosphere via the flue pipe with traditional boilers. The waste gasses that conveyed heat and could otherwise be used to generate heat were considered a safety risk due to the potential of building up too much pressure.

With condensing boilers, the cold water from the radiators returns into the system. Latent heat is absorbed before condensing. After being carefully emptied away, the extra condensed water is disposed of. The water keeps flowing through the chamber, absorbing the heat, and then returning to the system as hot water heads for the radiators.

As a result, a condensing boiler provides the same amount of heat output as a non-condensing boiler, but it also results in greater energy savings because more heat is taken from, and transferred to, the water that returns to the radiators. Condensing boilers can consume less fuel to supply the same amount of central heating as non-condensing boilers since they recycle this extra heat. This indicates that they attain an efficiency of over 90%.

Types of Condensing Boilers

The different types of condensing boilers include:

Combi Boilers

The most contemporary type of boiler is the combi boiler, and it has grown to be the type of boiler now used most often. Combi boilers are single, cost-effective machines that offer heating and hot water on demand without the need for any extra tanks or cylinders.

System Boilers

System boilers are comparable to combi boilers in that they use water from the mains. The distinction is that hot water is kept in a hot water cylinder with system boilers rather than being delivered on demand. This indicates that system boilers, as opposed to combi boilers, can handle greater capacity for facilities needing hot water.

Regular Boilers

Regular boilers are also known as conventional, heat-only, or open-vent boilers. They are the oldest type of boiler and are frequently seen in big, old houses. Water is fed to the boiler from a cold water tank in the loft rather than straight from the mains. The residential hot water is then kept in a cylinder while the boiler heats the central heating system directly.

Advantages of Condensing Boilers

- The efficiency of condensing boilers is typically 15 to 30 percent higher than that of non-condensing boilers. For instance, an A-rated (condensing) boiler is at least 90% efficient, whereas a G-rated (non-condensing) boiler may only be 60% efficient.

- When a boiler performs at a high degree of efficiency, it can use less fuel to provide the same level of central heating. Lower fuel usage will then translate into lower energy costs.

- Condensing boilers help homes cut their annual overall carbon footprint by up to 3 tonnes (over 6,600 lbs.) of CO2 since they use less fuel.

- Condensing boilers conserve space because they don't need the same type of ventilation as non-condensing units do.

- Condensing boilers are sealed systems as opposed to non-condensing boilers, which draw air from the building. They only breathe outside air that enters the building through the flue pipe. In the event of a problem, additional safety mechanisms such as pressure release valves will shut off the boiler.

Common Problems Encountered With Condensing Boilers

- Any amount of water coming from the heating system, no matter how minor, should be taken seriously. A heating engineer will be required to evaluate the problem and make the necessary repairs if there are leaks or drips for any variety of reasons.

- There are a variety of reasons why the heating or hot water may not turn on when users expect it to. The majority of problems will require the services of a heating specialist, but it's worthwhile to perform a few inspections first. Checking that the thermostat is operational and properly set should be the first step. The second most likely possibility is that the boiler pressure is inadequate.

Choosing the Proper Condensing Boilers Manufacturer

To make sure you have the most positive outcome when purchasing Condensing Boilers from a Condensing Boilers Manufacturer, it is important to compare at least 4 Suppliers using our Condensing Boilers directory. Each Condensing Boilers Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Condensing Boilers company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Condensing Boilers companies with the same quote.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services