Low pressure boilers are often box-like and constructed from stainless steel, aluminum, steel or cast iron. Inside the housing is a furnace to burn the fuel and an arrangement of pipes, valves and drums. The flue is the chimney that releases the steam into the system or atmosphere. Read More…

We strive for the best at Unilux Advanced Manufacturing LLC. Our boilers are designed with superior materials. We are proud to say that we produced the world's first UL/FE boiler and our units provide the highest levels of safety and accountability.

As the inventor of the vertical tubeless boiler, Fulton has a reputation for success dating back to 1949. We`re a global manufacturer of steam, hot water and hydronic boilers, thermal fluid heaters, and custom engineered systems.

Miura Boiler Co., Ltd. has been manufacturing, designing, engineering and servicing gas, oil, coal, wood, solid waste, biomass & hybrid fuel-fired steam & gas and condensing since our inception. With installations across all industries worldwide, We are recognized for the highest code standards, innovative engineering and design, Energy Star rating, fully Integrated controls, and renewable,...

Indeck has the largest inventory of steam generating systems, a custom boiler design team and our own boiler manufacturing plant . Indeck is the complete steam power solution provider with emergency rental of 25,000 pph trailer-mounted rental boilers to the design of large custom million pound boilers. Our expertise includes watertube, mobile, packaged, waste heat, solid fuel, biomass and fire...

At California Boiler, we dedicate ourselves to delivering high-performance boiler solutions that meet the diverse needs of industries across the region. As a team, we design, supply, and support a full range of boiler systems, from standard hot water and steam units to specialized, high-capacity equipment tailored to unique applications.

At Burnham Commercial Boilers, we take pride in being a trusted name in the manufacturing and engineering of high-quality boilers designed to deliver dependable heating solutions for commercial and industrial applications. With decades of experience and innovation behind us, we focus on building equipment that meets the rigorous demands of facilities that require reliable performance, energy...

Nationwide Boiler is a leading supplier of new and reconditioned boilers for industrial facilities worldwide. We’re a manufacturer’s representative and stocking distributor for B&W package watertube boilers and Superior package firetube boilers, and we have fully reconditioned boilers in a variety of types and sizes. With sales, service and equipment depots throughout the U.S., we strive to...

More Low Pressure Boiler Manufacturers

Low Pressure Boilers: Comprehensive Guide to Applications, Benefits, and Selection

Low pressure boilers play an essential role in industrial, commercial, and manufacturing environments, providing a reliable and efficient source of steam for various process and heating applications. Unlike their high pressure counterparts, low pressure boilers are specifically engineered to operate below certain pressure thresholds, making them ideal for situations that do not require the intense pressure levels associated with power generation or heavy manufacturing. In this in-depth guide, we’ll explore how low pressure boilers work, their most common uses, benefits, and key factors to consider when selecting a low pressure boiler system for your facility.

What Are Low Pressure Boilers?

Low pressure boilers are steam or hot water boilers designed to operate at a maximum allowable working pressure (MAWP) that is lower than that of high pressure boiler systems. For steam boilers, this typically means operating at or below 15 psi (pounds per square inch), while hot water boilers classified as low pressure generally operate at or below 160 psi and temperatures not exceeding 250°F. These thresholds are defined by standards such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, which governs boiler safety and operation in the United States and globally.

Unlike high pressure boilers, which are frequently used in power plants, refineries, and heavy industrial settings, low pressure boilers are most commonly employed for generating steam for process requirements such as space heating, humidification, sterilization, and cleaning. They are also used in food processing, breweries, laundry facilities, and smaller manufacturing operations where moderate steam outputs are sufficient.

How Do Low Pressure Boilers Work?

Understanding the fundamental operation of a low pressure boiler is crucial for facility managers, plant engineers, and maintenance professionals looking to optimize energy efficiency and safety:

- Heat Generation: Low pressure boilers use a fuel source—such as natural gas, oil, propane, coal, or biomass—to create heat. This heat is transferred to water within the boiler vessel.

- Steam Production: As the water absorbs the thermal energy, it turns into steam (or remains hot water, depending on the boiler configuration). The system is engineered to maintain steam pressure at or below the designated low pressure threshold.

- Distribution: The produced steam or hot water is distributed throughout the facility for end uses like space heating, process heating, or sanitation.

- Safety Controls: All low pressure boilers are equipped with safety valves, pressure relief devices, and monitoring controls to ensure safe operation and compliance with local and national codes.

There are two main types of boiler designs used for low pressure applications:

Fire-Tube Boilers

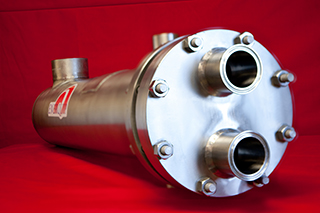

Fire-tube boilers direct the heat produced from burning fuel through a series of tubes that are immersed in water. As the heated tubes transfer thermal energy to the surrounding water, steam is generated and collected for use. Fire-tube boilers are generally preferred for low pressure steam and hot water applications because of their simple design, ease of maintenance, and cost-effectiveness. These are popular in commercial heating, institutional buildings, and small-to-medium-sized industrial plants.

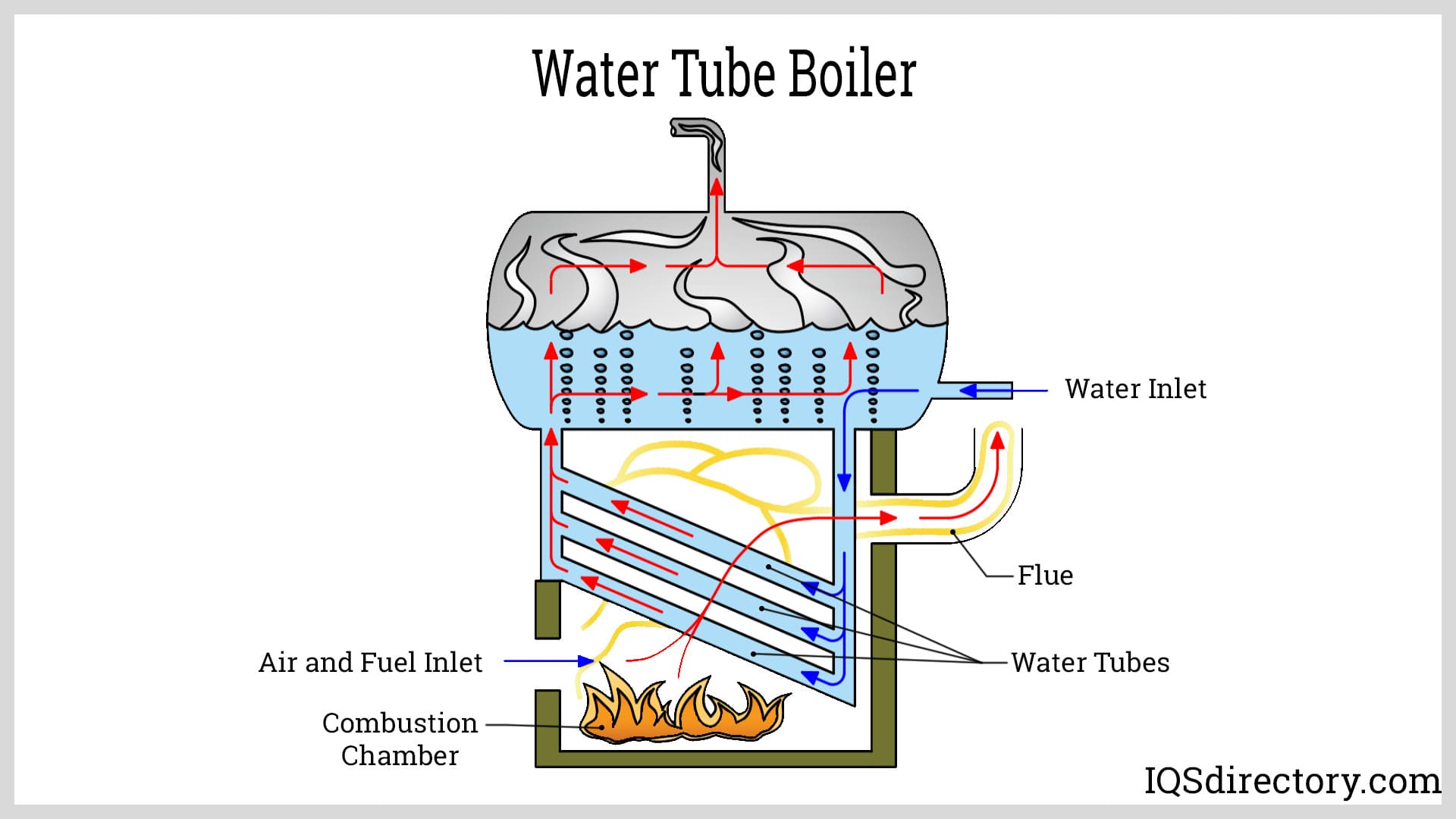

Water-Tube Boilers

Water-tube boilers have a different construction: water flows inside the tubes, which are externally heated by combustion gases. This design is more typical for high pressure applications, as water-tube boilers can withstand higher pressures (often up to 1,000 psi or more). However, there are also water-tube boilers designed for low pressure operation, especially where rapid steam generation is important and space is a constraint.

Key Applications of Low Pressure Boilers

Low pressure boilers are incredibly versatile and are found across a wide range of industries and facilities. Some of the most common applications include:

- Space Heating: Providing comfortable and consistent heating in commercial buildings, schools, hospitals, apartment complexes, and hotels.

- Process Steam: Supplying steam for sterilization, cleaning, humidification, and food processing in smaller manufacturing plants, breweries, commercial laundries, and bakeries.

- District Heating: Used in centralized heating plants to distribute steam or hot water to multiple buildings or facilities.

- Greenhouses: Maintaining optimal growth temperatures for plants in agricultural and horticultural operations.

- Healthcare Facilities: Sterilization of medical equipment, heating, and humidification for patient comfort and safety.

- Educational Institutions: Efficient and reliable heating for campuses and classrooms.

Low Pressure Boilers vs. High Pressure Boilers

When selecting a boiler system, it’s important to understand the key differences between low pressure and high pressure boilers—and how these differences impact safety, efficiency, and maintenance needs:

- Operating Pressure: Low pressure boilers operate at a maximum of 15 psi for steam and 160 psi for hot water, while high pressure boilers exceed these limits.

- Safety: Low pressure boilers are inherently safer, as their lower operating pressures reduce the risk of catastrophic failure and simplify compliance with safety codes and regulations.

- Maintenance: These systems typically require less intensive maintenance than high pressure boilers, resulting in lower operating costs over their lifetime.

- Cost: Low pressure boilers are often less expensive to install and operate, making them a cost-effective choice for many businesses.

- Application Suitability: High pressure boilers are necessary for applications that demand high temperature and pressure steam, such as power generation, chemical processing, or large-scale manufacturing.

Curious about the pros and cons of low vs. high pressure systems for your facility? Contact our experts for a custom assessment of your operational needs.

Advantages and Benefits of Low Pressure Boilers

Low pressure boilers offer a range of compelling benefits for operators looking to balance efficiency, safety, and cost:

- Enhanced Safety: Lower operating pressures reduce the risk of dangerous explosions and make routine inspections and maintenance easier to perform.

- Simplified Regulatory Compliance: Many jurisdictions have less stringent inspection and certification requirements for low pressure boilers, streamlining the approval process.

- Lower Installation and Operating Costs: These systems are generally more affordable to purchase, install, and operate, with reduced maintenance and energy expenses compared to high pressure alternatives.

- Energy Efficiency: Modern low pressure boilers are designed for optimal fuel-to-steam efficiency, helping facilities reduce their carbon footprint and control energy costs.

- Compact Footprint: Because they do not require thick-walled pressure vessels or complex support systems, low pressure boilers can be installed in smaller spaces, freeing up valuable square footage for other operations.

- Flexibility: Suitable for a wide range of heating and process applications, with both fire-tube and water-tube options available.

Buyer’s Guide: How to Choose the Right Low Pressure Boiler

Selecting the optimal low pressure boiler for your facility is a strategic decision that impacts long-term operational efficiency, safety, and costs. Here are key factors to consider when evaluating low pressure boilers for purchase or replacement:

- Capacity and Output: Assess your facility’s steam or hot water demand to determine the appropriate boiler size, measured in horsepower (HP), British thermal units (BTUs), or pounds of steam per hour (PPH).

- Fuel Type: Decide whether natural gas, oil, propane, electric, or alternative fuels best align with your infrastructure, fuel availability, and sustainability goals.

- Efficiency Ratings: Compare thermal efficiency ratings and look for features such as condensing technology, modulating burners, and high turndown ratios to maximize fuel savings.

- Controls and Automation: Advanced control systems can monitor water levels, pressure, temperature, and fuel flow for greater reliability and ease of use. Consider boilers with integrated remote monitoring and IoT capabilities for proactive maintenance.

- Maintenance and Serviceability: Choose designs that facilitate easy access to key components, with clear maintenance schedules and available service support.

- Compliance and Certification: Ensure the boiler meets all relevant ASME, UL, and local codes, and check for third-party certifications that indicate quality and safety.

- Warranty and Support: Evaluate manufacturer warranties, available spare parts, and after-sales service for ongoing peace of mind.

- Scalability: If your facility may expand in the future, consider modular or scalable boiler systems that can grow with your needs.

Common Questions About Low Pressure Boilers

- What are the main differences between a low pressure steam boiler and a low pressure hot water boiler?

A low pressure steam boiler produces steam at or below 15 psi, typically for space heating or process use. A low pressure hot water boiler operates at pressures up to 160 psi and temperatures up to 250°F, distributing heated water throughout a facility’s piping system. - Who regulates boiler safety standards?

Boiler operation and safety are regulated by organizations such as the ASME, as well as local and state agencies. Always ensure your boiler is compliant with all applicable codes and standards. - How often should a low pressure boiler be inspected?

Inspection frequency depends on local regulations and manufacturer recommendations, but most low pressure boilers should be checked at least annually by a qualified technician. - What is flash steam, and how is it used?

Flash steam occurs when high pressure steam is suddenly depressurized, causing some of the condensate to instantly re-evaporate. This flash steam can be recovered and used in low pressure boilers for improved energy efficiency. - Can low pressure boilers be used in residential settings?

While technically possible, residential heating systems usually utilize other technologies, such as combi boilers or furnaces, as low pressure boilers are optimized for larger commercial and industrial applications. - What maintenance tasks are most important for low pressure boilers?

Key maintenance activities include regular water level checks, blowdown procedures, inspection of safety valves and controls, burner cleaning, and ensuring proper water treatment to prevent scale and corrosion.

Low Pressure Boiler System Integration and Upgrades

Integrating a new low pressure boiler into your facility or upgrading an existing system can deliver significant operational benefits. Modern low pressure boilers are designed for compatibility with advanced building automation systems and can be retrofitted into older plants to improve efficiency, safety, and emissions compliance.

Key considerations for successful integration include:

- System Compatibility: Ensure the new boiler works seamlessly with your existing piping, controls, and distribution infrastructure.

- Energy Recovery: Consider incorporating economizers, condensate return systems, and flash steam recovery for additional energy savings.

- Emission Controls: Upgrading to low NOx burners or implementing exhaust treatment technologies can help meet stringent environmental regulations.

- Remote Monitoring: Automated monitoring and diagnostic tools allow for predictive maintenance and rapid troubleshooting, minimizing downtime.

Case Studies: Real-World Low Pressure Boiler Solutions

Organizations across industries have realized substantial benefits by deploying low pressure boilers tailored to their specific needs. Here are a few examples:

- Commercial Laundry: A large laundry facility upgraded to a modular low pressure steam boiler system, reducing fuel costs by 20% while improving cycle times and workflow efficiency.

- Healthcare Campus: A hospital integrated a new low pressure hot water boiler with advanced controls, resulting in more stable indoor temperatures and lower maintenance overhead.

- Food Processing Plant: A mid-sized processor replaced outdated high pressure steam units with modern low pressure boilers, achieving compliance with updated safety codes and reducing emissions by 30%.

- School District: A multi-campus school system centralized its heating plant with low pressure boilers and a district steam network, cutting energy expenditures and simplifying maintenance scheduling.

Conclusion: Maximize Facility Performance with Low Pressure Boilers

Low pressure boilers offer a safe, efficient, and cost-effective solution for a wide variety of steam and hot water needs in commercial and industrial environments. By understanding the types, benefits, and decision factors, facility managers and engineers can make informed choices that maximize uptime, minimize costs, and simplify regulatory compliance.

Whether you’re installing a new system, upgrading an existing plant, or evaluating boiler replacement options, ensuring proper sizing, fuel selection, and integration will deliver long-term operational and financial benefits. For expert guidance and a tailored solution, consult with experienced boiler professionals who understand your industry’s unique requirements.

Ready to take the next step? Request a quote or consultation today and discover how a low pressure boiler system can help your facility achieve its safety, efficiency, and sustainability goals.

For more information on industrial, commercial, or manufacturing boiler solutions—including high pressure, condensing, and modular boiler systems—visit our main boiler resource center.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

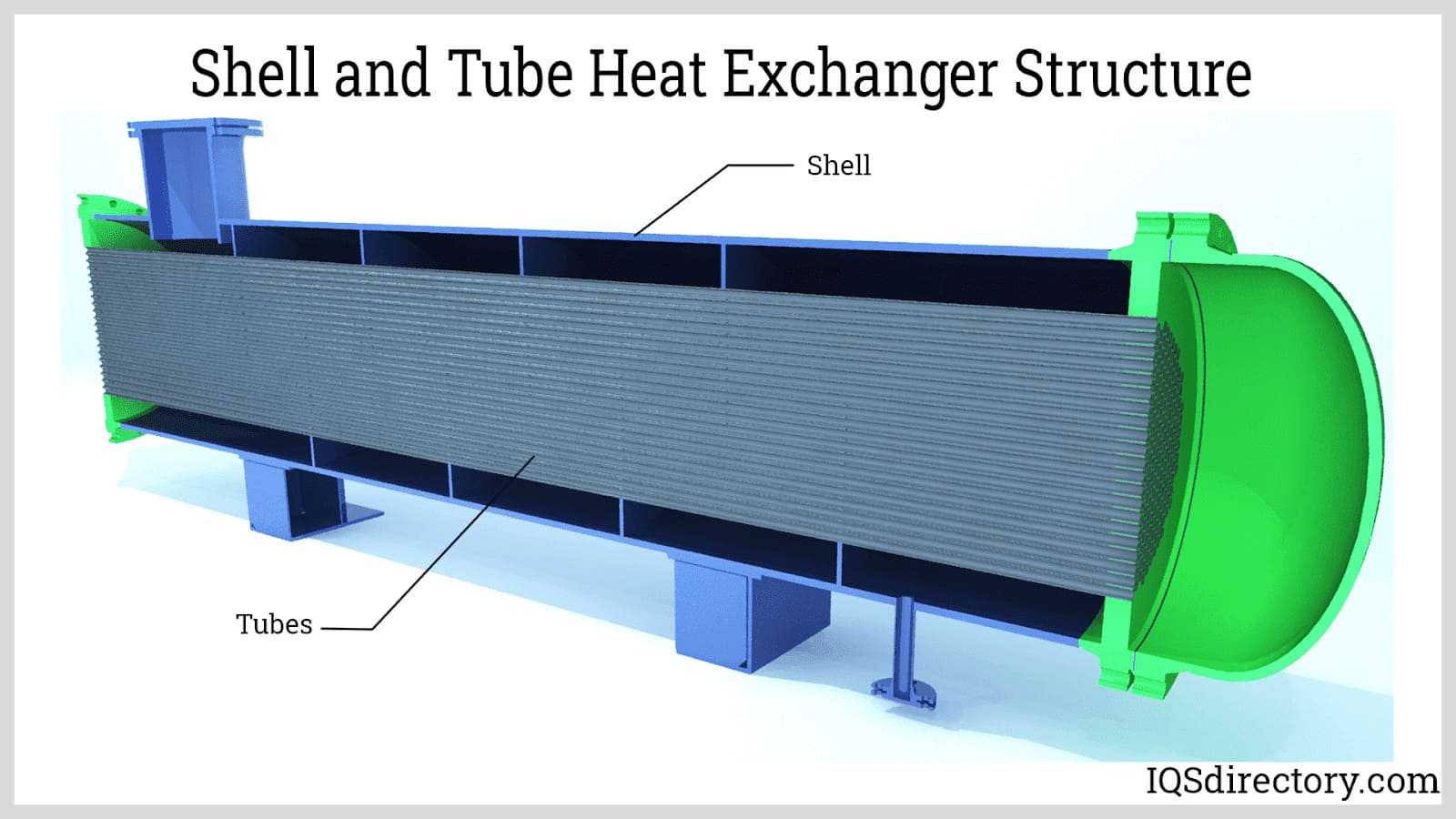

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services