An oil boiler is a device that uses oil to heat water, which is then circulated through radiators or underfloor pipes to provide heat. They are a popular choice for heating buildings and providing hot water due to their reliability, versatility, and long lifespan. Read More…

We strive for the best at Unilux Advanced Manufacturing LLC. Our boilers are designed with superior materials. We are proud to say that we produced the world's first UL/FE boiler and our units provide the highest levels of safety and accountability.

As the inventor of the vertical tubeless boiler, Fulton has a reputation for success dating back to 1949. We`re a global manufacturer of steam, hot water and hydronic boilers, thermal fluid heaters, and custom engineered systems.

Miura Boiler Co., Ltd. has been manufacturing, designing, engineering and servicing gas, oil, coal, wood, solid waste, biomass & hybrid fuel-fired steam & gas and condensing since our inception. With installations across all industries worldwide, We are recognized for the highest code standards, innovative engineering and design, Energy Star rating, fully Integrated controls, and renewable,...

Indeck has the largest inventory of steam generating systems, a custom boiler design team and our own boiler manufacturing plant . Indeck is the complete steam power solution provider with emergency rental of 25,000 pph trailer-mounted rental boilers to the design of large custom million pound boilers. Our expertise includes watertube, mobile, packaged, waste heat, solid fuel, biomass and fire...

At California Boiler, we dedicate ourselves to delivering high-performance boiler solutions that meet the diverse needs of industries across the region. As a team, we design, supply, and support a full range of boiler systems, from standard hot water and steam units to specialized, high-capacity equipment tailored to unique applications.

At Burnham Commercial Boilers, we take pride in being a trusted name in the manufacturing and engineering of high-quality boilers designed to deliver dependable heating solutions for commercial and industrial applications. With decades of experience and innovation behind us, we focus on building equipment that meets the rigorous demands of facilities that require reliable performance, energy...

Nationwide Boiler is a leading supplier of new and reconditioned boilers for industrial facilities worldwide. We’re a manufacturer’s representative and stocking distributor for B&W package watertube boilers and Superior package firetube boilers, and we have fully reconditioned boilers in a variety of types and sizes. With sales, service and equipment depots throughout the U.S., we strive to...

More Oil Boiler Manufacturers

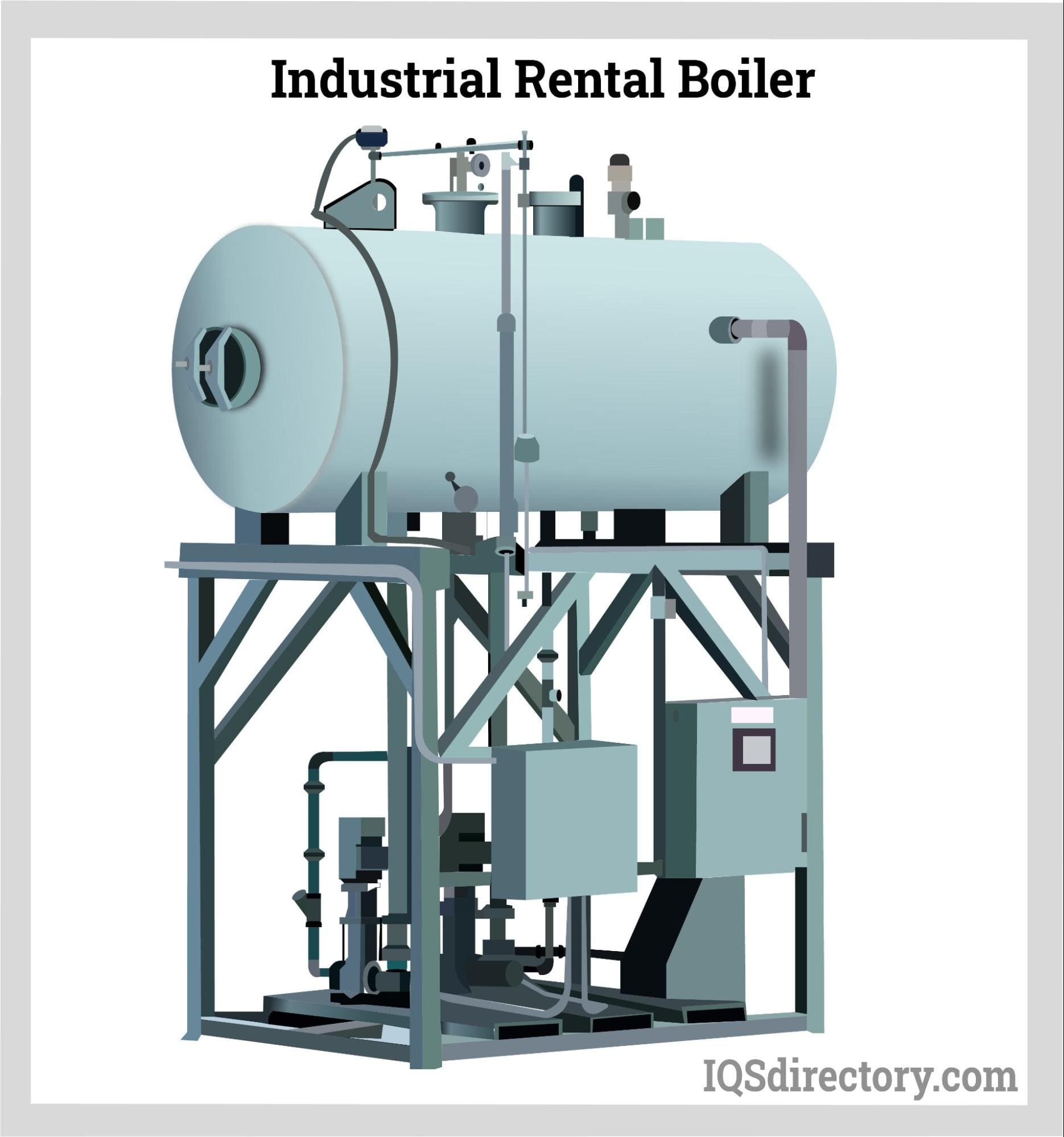

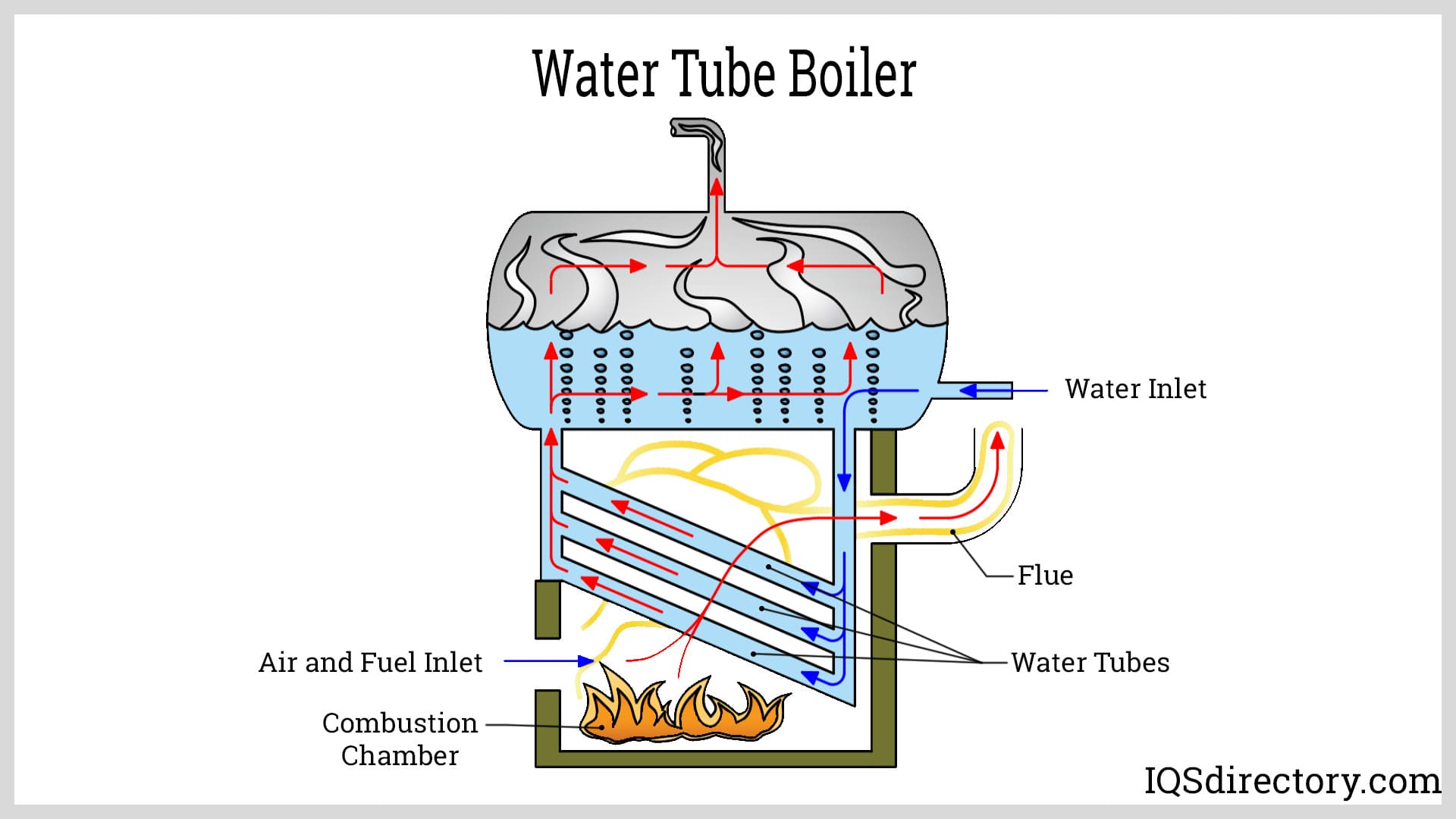

Components of Oil Boilers

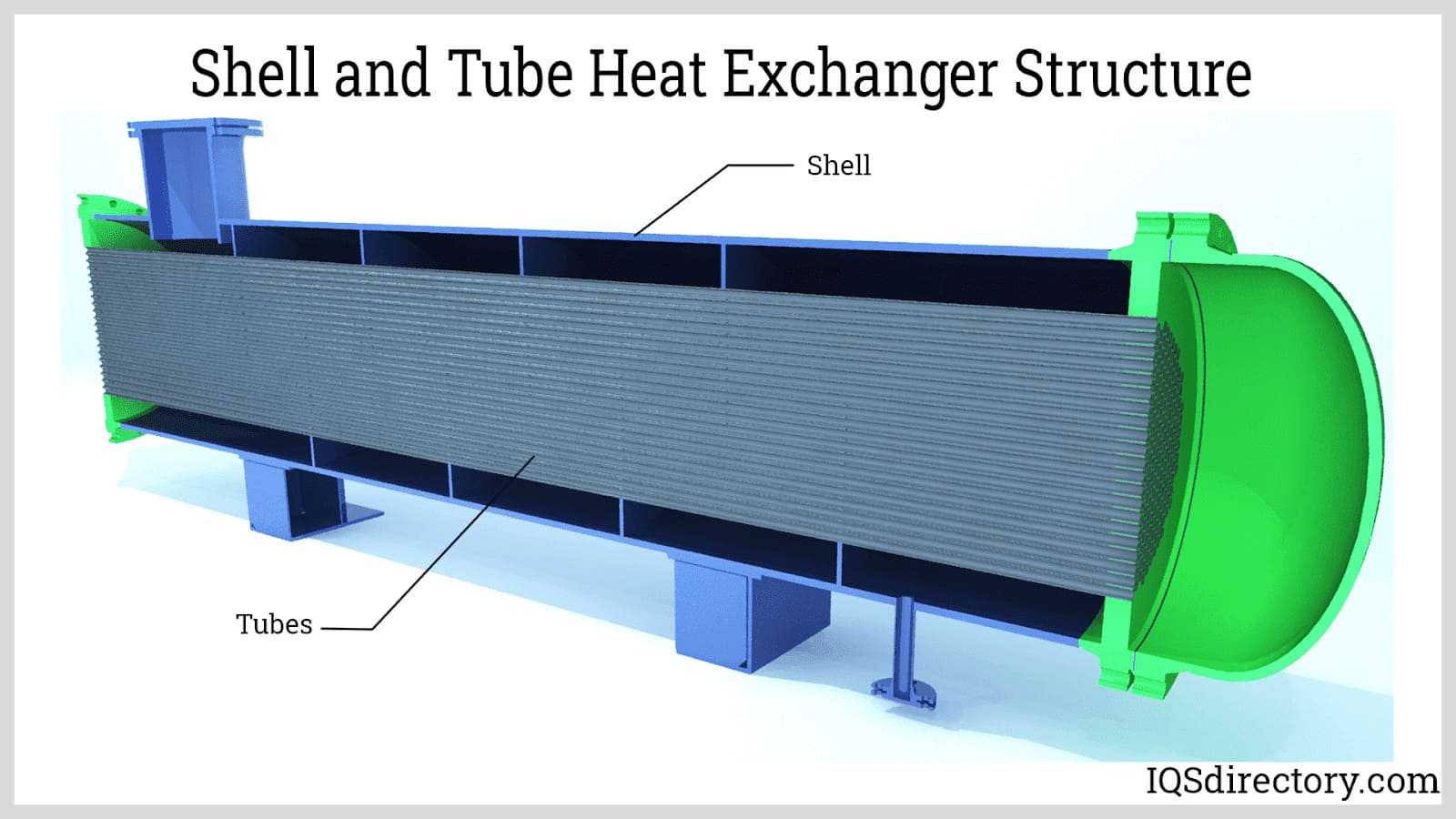

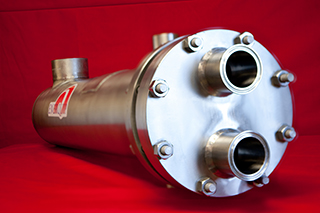

Oil boilers are composed of several components that work together to create heat. These components include the burner, combustion chamber, heat exchanger, fuel supply system, controls, circulation pump, and vent pipe. The fuel supply system is responsible for delivering oil to the burner, which is then ignited in the combustion chamber. The heat exchanger transfers the heat generated in the combustion chamber to the water circulating through it. The circulation pump moves the heated water to the desired location, and the vent pipe allows exhaust gasses to escape.

Variations of Oil Boilers

There are two main design variations of oil boilers, including standard efficiency and high-efficiency models. The main difference between standard efficiency and high-efficiency models of oil burners is their level of energy efficiency. Standard efficiency oil burners typically have an efficiency rating of 80% to 85%, meaning that 15% to 20% of the fuel they consume is lost as waste heat. In contrast, high-efficiency oil burners have an efficiency rating of 90% to 95%, meaning that they waste less fuel and are more energy-efficient overall.

The primary reason for this difference in efficiency is the way in which the burners are designed. High-efficiency oil burners are designed to extract more heat from the fuel, using advanced technologies such as sealed combustion chambers and condensing heat exchangers to minimize waste. They also typically have more advanced controls and sensors to optimize performance and minimize fuel consumption. However, high-efficiency oil burners are more expensive to construct and install. Overall, the choice between standard efficiency and high-efficiency oil burners will depend on factors such as budget, energy needs, and long-term goals for energy efficiency and sustainability.

Considerations Regarding Oil Boilers

One of the most significant considerations of oil boilers is their impact on the environment. Burning oil releases carbon dioxide and other greenhouse gasses, contributing to climate change. Additionally, the price of oil can fluctuate, making it difficult to predict and manage fuel costs. Finally, oil boilers require regular maintenance and repair, which can be costly and time-consuming.

Benefits of Oil Boilers

Despite these considerations, there are many benefits to using oil boilers for heating. One of the most significant advantages is their energy efficiency. They can be up to 90% efficient, meaning that almost all the fuel used is converted into heat. This efficiency can offset the cost of fuel, making oil boilers very cost-effective in the long run. Additionally, they are reliable, versatile, and have a long lifespan, often lasting up to 20 years with proper maintenance.

Oil boilers also have several benefits over other types of boilers. Compared to gas boilers, for instance, oil boilers have a more consistent fuel supply because the supply of oil is more stable and predictable than that of natural gas, making them a more reliable choice. Additionally, electric boilers can be more expensive to operate, especially in areas where electricity is expensive. Finally, solid fuel boilers require more manual labor, and the fuel can be messy and difficult to store.

Applications of Oil Boilers

Oil boilers can be used for a wide range of applications, including:

Heating Homes

Oil boilers are a popular choice for heating homes of all sizes. They work by heating water, which is then circulated through radiators or underfloor heating systems to warm the space.

Water Heating

In addition to space heating, oil burners can also be used to heat water for domestic use, such as showers, baths, and washing dishes. Hot water is generated by heating water in a tank or cylinder, which is then distributed through pipes to the various fixtures throughout the home or building.

Industrial Heating

Oil burners are also used for industrial heating applications, such as heating large warehouses or manufacturing facilities. They can provide efficient and cost-effective heating solutions for a wide range of industrial processes.

Power Generation

Oil burners are commonly used in power generation applications, such as backup generators for hospitals, data centers, and other critical facilities. They can provide reliable power in the event of a power outage or other emergency situation.

Boilers

Oil burners are a common component in boilers of all types, including steam boilers, hot water boiler, and thermal oil boilers. They provide efficient and reliable heat for a variety of applications.

Cooking

Oil burners can be used for cooking applications, such as in commercial kitchens or for outdoor cooking appliances like grills and fryers.

Drying

Oil burners are often used for drying applications, such as in industrial dryers or grain drying facilities.

Asphalt Production

Oil burners are commonly used in asphalt production plants, where they provide heat for the production of asphalt and related products.

Chemical Processing

Oil burners can be used in a variety of chemical processing applications, such as heating reactors or distillation columns.

Waste Management

Oil burners can also be used for waste management applications, such as in incinerators or waste-to-energy facilities.

Choosing the Proper Oil Burner Supplier

To ensure you have the most beneficial outcome when purchasing an oil burner from an oil burner supplier, it is important to compare several companies using our directory of oil burner suppliers. Each oil burner supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each oil burner business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple oil burner companies with the same form.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services