When heat energy is applied to water, a steam boiler—a steel-built power generation device—generates steam. Older boilers operate in the low to medium pressure range (7 kPa to 2000 kPa/ 1 psi to 290 psi). Because they operate under higher pressure than older ones, the current boilers are more practical. The vapor produced may be delivered at low pressure for industrial advancement tasks in cotton mills and sugar refineries and for creating steaming water that can be used for heat-fixing at very low pressure. Read More…

We strive for the best at Unilux Advanced Manufacturing LLC. Our boilers are designed with superior materials. We are proud to say that we produced the world's first UL/FE boiler and our units provide the highest levels of safety and accountability.

As the inventor of the vertical tubeless boiler, Fulton has a reputation for success dating back to 1949. We`re a global manufacturer of steam, hot water and hydronic boilers, thermal fluid heaters, and custom engineered systems.

Miura Boiler Co., Ltd. has been manufacturing, designing, engineering and servicing gas, oil, coal, wood, solid waste, biomass & hybrid fuel-fired steam & gas and condensing since our inception. With installations across all industries worldwide, We are recognized for the highest code standards, innovative engineering and design, Energy Star rating, fully Integrated controls, and renewable,...

Indeck has the largest inventory of steam generating systems, a custom boiler design team and our own boiler manufacturing plant . Indeck is the complete steam power solution provider with emergency rental of 25,000 pph trailer-mounted rental boilers to the design of large custom million pound boilers. Our expertise includes watertube, mobile, packaged, waste heat, solid fuel, biomass and fire...

At California Boiler, we dedicate ourselves to delivering high-performance boiler solutions that meet the diverse needs of industries across the region. As a team, we design, supply, and support a full range of boiler systems, from standard hot water and steam units to specialized, high-capacity equipment tailored to unique applications.

At Burnham Commercial Boilers, we take pride in being a trusted name in the manufacturing and engineering of high-quality boilers designed to deliver dependable heating solutions for commercial and industrial applications. With decades of experience and innovation behind us, we focus on building equipment that meets the rigorous demands of facilities that require reliable performance, energy...

Nationwide Boiler is a leading supplier of new and reconditioned boilers for industrial facilities worldwide. We’re a manufacturer’s representative and stocking distributor for B&W package watertube boilers and Superior package firetube boilers, and we have fully reconditioned boilers in a variety of types and sizes. With sales, service and equipment depots throughout the U.S., we strive to...

More Steam Boiler Manufacturers

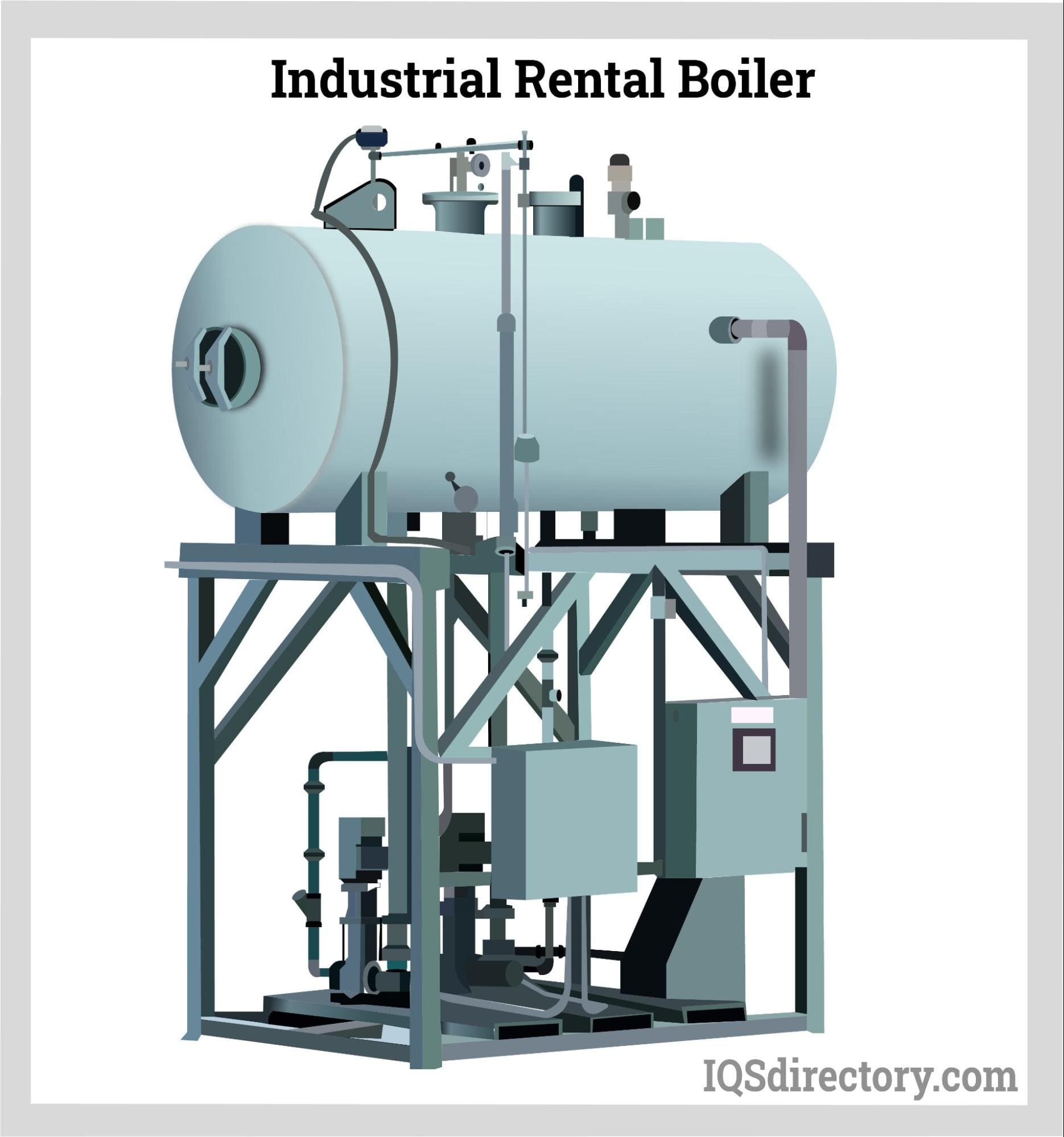

The size and type of this boiler largely depend on the application, such as mobile steam engines, which include handy engines, steam locomotives, and road vehicles. This boiler is frequently used whenever a steam source is required. These automobiles have a small boiler that can be operated by steam. Typically, stationary steam engines or power plants have a huge steam-generating capacity.

The Function of Steam Boilers

A steam boiler's primary duties include creating, storing, and disturbing the vapor. The liquid-filled boiler is nothing more than a shell, and the heat energy generated during fuel combustion is transferred to water before being converted into steam at the requisite pressure and temperature. The water container must lock extremely carefully; this ability to lock is one of the essential requirements for this boiler. The chosen circumstances should be provided for the water vapor, meaning the desired quality, pace, pressure, and temperature.

Steam Boiler Working Principle

A steam boiler's primary operating concept is simple. This boiler is an example of a closed cylindrical apparatus. The boiler's capacity to hold both water and steam is adequate. Typically, liquids are kept in boilers to produce steam by burning fuels or applying heat energy under various pressures based on the size and specifications of the vessel. Finally, a pipe is used to supply the boiler's steam, which flows into different fields like plants. The essential parts of this boiler are the furnace, grate, mountings, water space, accessories, refectory, water level, scale, foaming, lagging, and blowing off.

Types of Steam Boilers

According to their needs, steam boilers are divided into wide varieties.

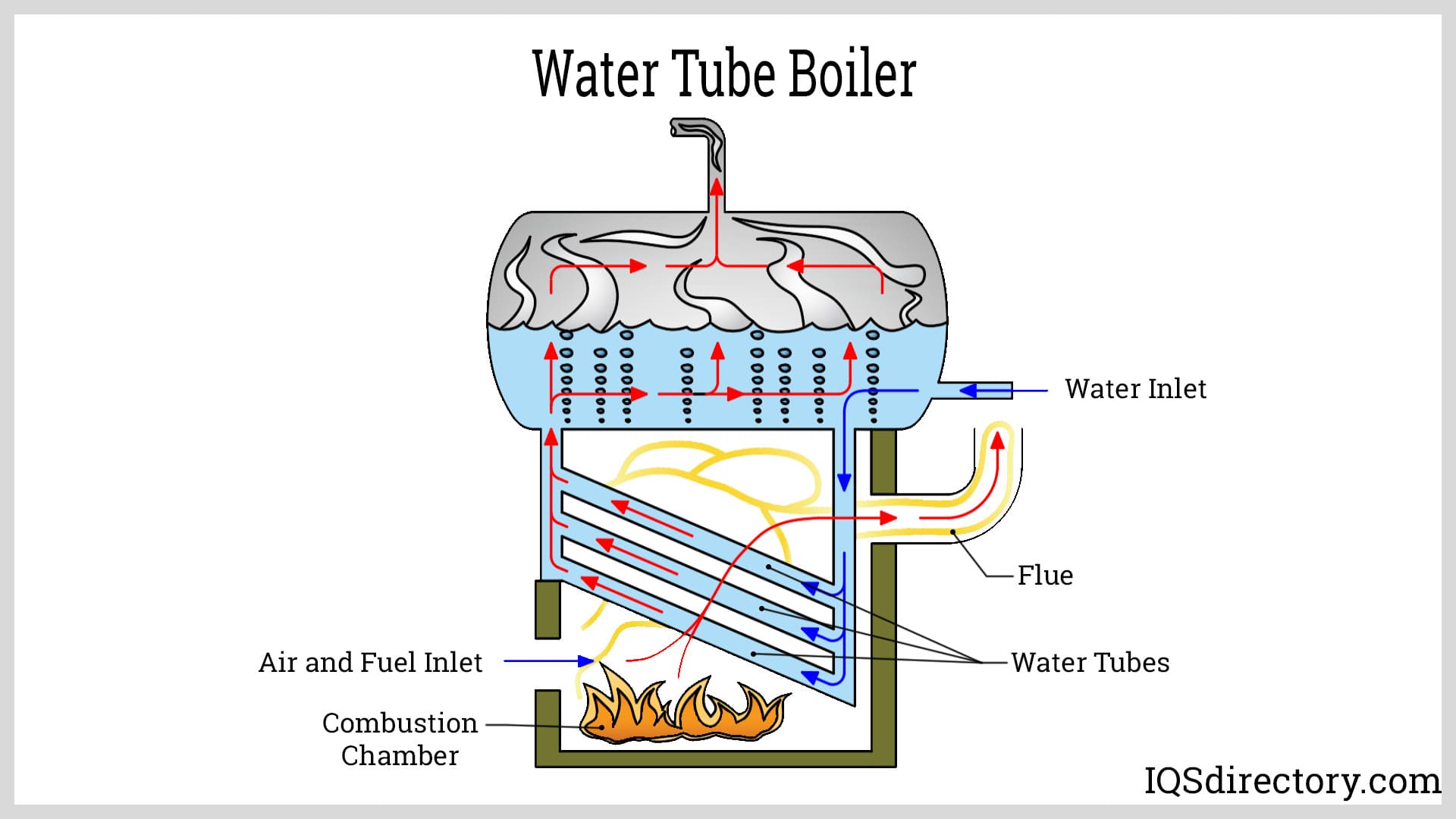

Water Tube Boilers

The primary purpose of the water tube boiler, one form of the boiler, is to heat the water in the tube to produce vapor. Utilizing this boiler in large thermal power plants is one of its key advantages. A large heating surface can be achieved by utilizing several water tubes. The heat transfer rate is quite high because of the water's rapid velocity, which results in great efficiency. This boiler needs fresh water and water treatment facilities to maintain the required quality of water tube boilers.

Fire Tube Boilers

This boiler can be constructed with numerous tubes to feed the hot gases. In a sealed container, these tubes are absorbed by water. The heated tubes are sent via a single closed container in this boiler. Water is heated in these tubes to turn to vapor, which condenses back into a similar container. A fire-tube boiler cannot produce vapor with high force when water and vapor are in the same container. It can generally produce a maximum of 17.5 kg/cm2 and a nine metric ton capacity of steam per hour.

Package Boilers

A package boiler is a discrete application that uses an integrated burner powered by oil or gas to provide energy. This boiler can produce large amounts of steam at both high pressure and high temperature. Also, this boiler operates variable loads with a quick start-up or response time. The major uses for this boiler are to process steam for industrial, chemical, or employed as a steam turbine power generator. In addition, the package boiler can also be used as a peak-load boiler because of a backup power source that comes on when other supplies fail.

Stoker Fired Boilers

The common range and cogeneration systems in sugar factories are where the stoker-fired boiler excels. These boilers work entirely automatically and have a membrane design. These boilers have built-in characteristics for trouble-free, high-thermal efficiency operation. These are categorized according to the method used to provide fuel to the boiler and the grate type. The two types of stoker-fired boilers are chain-grate or traveling grate stokers and spreader stokers.

Advantages of Steam Boilers

The advantages of this boiler are as follows.

- These boilers are inexpensive to build.

- Any chimney can be used with this boiler.

- Less floor space is needed for it.

- It's transportable.

- It has a boiler that is enclosed.

Disadvantages of Steam Boilers

The following are some of this boiler's drawbacks.

- The vertical construction of the steam boiler limits the amount of steam that can rise.

- Its pressure and capacity are constrained.

- These are challenging to clean and examine.

- It demands a lot of headspaces.

Applications of Steam Boilers

The following are some uses for this boiler.

- These are employed in steam turbines or engines to produce power.

- These are employed in several processes in the process industries.

- These are used in homes or buildings in cold weather to produce hot water.

Characteristics of Steam Boilers

The following are some characteristics of a steam boiler.

- The steam boiler produces the most steam using the least fuel.

- It must be lighter and take up less room.

- It must begin right away.

- These boilers must be inexpensive and low-maintenance.

- These boilers are capable of handling any varying load.

Choosing the Correct Steam Boiler Manufacturer

To make sure you have the most positive outcome when purchasing Steam Boilers from a Steam Boiler Manufacturer, it is important to compare at least 5 Companies using our Steam Boiler directory. Each Steam Boiler Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Steam Boiler company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Steam Boiler companies with the same quote.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

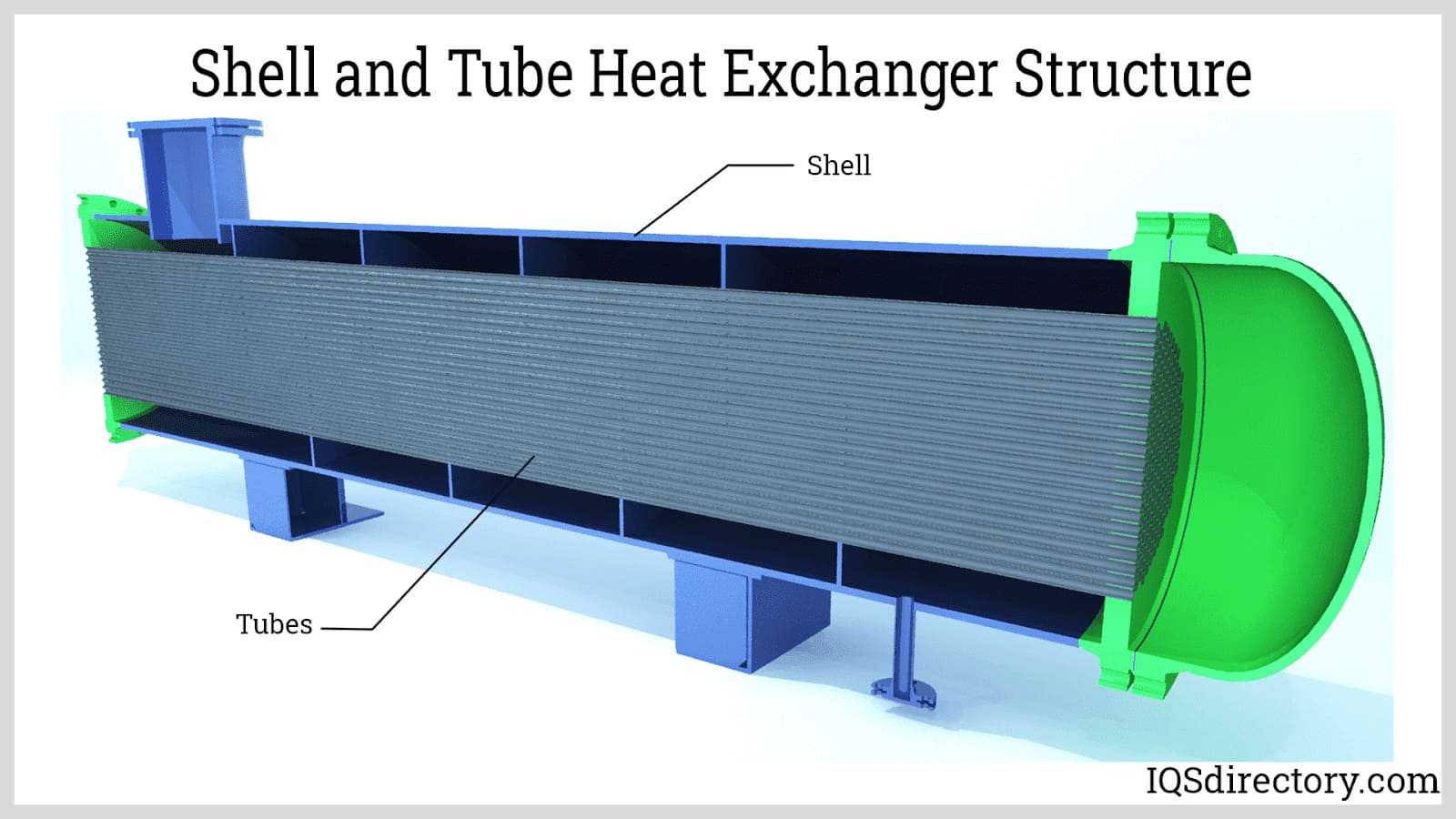

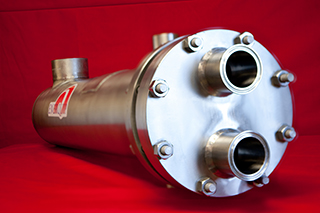

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services